Antong Product Packaging | Customized Export Packing for Terminal Blocks & Electrical Accessories

How Antong Professionally Packs Terminal Blocks for Global Shipping

As a factory with over 35 years of experience, Antong understands the paramount importance of delivering products that not only meet strict quality standards but also remain competitively priced in today’s global market.

All packaging processes are carried out under the SafeTypass quality system, ensuring consistency and reliability across every Antong product delivered worldwide.

In the terminal block industry, how terminal blocks are packed for export plays a vital role in product protection, cost control, and customer satisfaction.

At Antong Terminal Block, we recognize that efficient and safe packaging is essential for maintaining the integrity of electrical components during long-distance transportation. That’s why we’ve developed a professional packing process for terminal blocks and terminal strips—a system that prioritizes both safety and efficiency.

Tailored Packing Solutions for Electrical Accessories

We understand that one packing method does not fit all. Our approach is flexible and customized to suit the needs of each product. Whether you're ordering feedthrough terminal blocks, barrier terminal strips, or other electrical accessories, we ensure every item is packed with care to provide a snug fit and optimal protection during transit.

Packing Process for Feedthrough Terminal Blocks

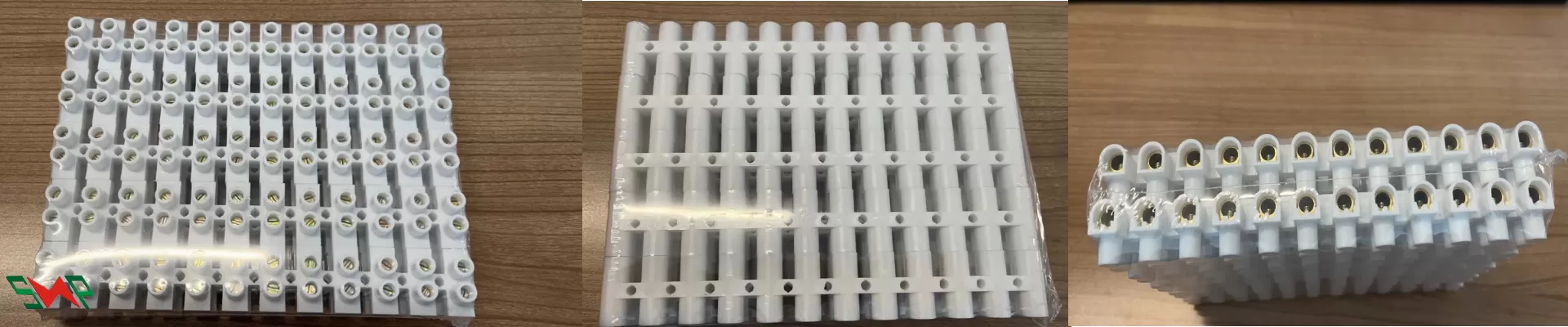

Step 1: We use heat-shrink film to bundle 10 feedthrough terminal blocks per pack. This method prevents collisions during transportation and helps customers quickly confirm the product count upon delivery.

Step 2: We utilize export-grade cartons, with the number of units per box depending on the product's size and weight. For exact figures, please refer to our product catalog, available in the Resource - Ebook section. Each carton is clearly labeled with quantity and gross weight. On request, we can also apply your brand’s logo or Antong’s official logo to the outer carton for enhanced brand visibility.

Customized Packing for Terminal Blocks

We understand that different business models and markets require different packaging styles. For example, retail packaging and OEM branding often require customized solutions. Our team works closely with trusted packaging partners to meet your specific requirements, whether it's custom box design, internal layout, or labeling.

Customized Packing Request

Due to varying product usage/selling scenarios, some customers may have custom packaging requirements. Our team strives to accommodate these requests and collaborates closely with trusted packaging partners to fulfill customer needs. As example shows below;

Note: To protect our clients’ confidentiality, some logos shown in the example images have been blurred or removed.